Decoupling and a shift in industry awareness are essential to the realization of Software-Defined Vehicle (SDV)Enhancing work efficiency through the use of Software-Defined Operation (SDO)

![]()

Hong Seok-Min, CEO of FESCARO

We are witnessing a mobility revolution,

with self-driving vehicles on the roads and seamless connectivity between

smartphones and vehicles. The future remains unpredictable as technology

rapidly advances. At 'AID 2024' (Automotive Innovation Day 2024), the largest

conference on cutting-edge automotive technology in Korea, one speaker captured

attention with the introduction of the Software-Defined Operation (SDO)

concept. He emphasized that 'in the mobility era, work processes must also

become software-centric.'

That speaker was Hong Seok-min, CEO of FESCARO,

a company specializing in future mobility software solutions. I had the

opportunity to meet CEO Hong to discuss his insights on the evolving automotive

industry.

What is the most notable keyword in the

mobility industry right now?

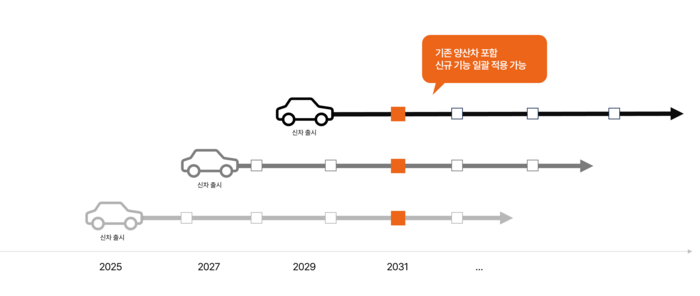

The most prominent keyword is undoubtedly 'SDV (Software-Defined Vehicle).'

Traditional internal combustion engine vehicles were hardware-centric, making

it challenging to modify functions after release. However, with SDVs, key

vehicle functions are controlled by software, allowing for performance

improvements through updates. Tesla is the leading example of this

transformation. By providing software updates, Tesla offers consumers enhanced

value consistently, demonstrating that a subscription model is feasible for

vehicles as well.

Source=FESCARO

When purchasing a vehicle, consumers

typically consider factors like design, brand, and price. However, Tesla has

demonstrated that the true demand lies in having a vehicle that remains

up-to-date over time. The SDV concept addresses this consumer need while also

offering automakers a new profit model.

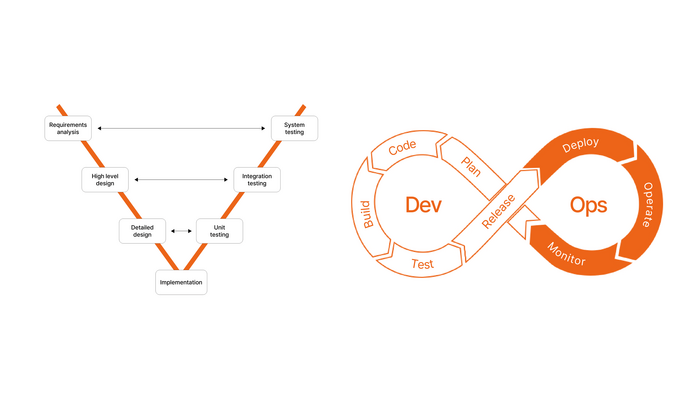

To realize the SDV, software development

methods are also evolving. The traditional V-model, which completes software

development by the mass production stage, faces limitations in improving

quality after mass production. To address this issue, a new methodology called

DevOps is gaining traction. DevOps integrates development and operations,

creating a continuous cycle from design to monitoring. This approach allows for

ongoing product improvements, enabling automakers to continuously enhance

competitiveness even after mass production.

Source=FESCARO

How should industry awareness change to

realize SDV?

In an evolving mobility landscape, it is crucial to first grasp the essence of

this shift. The focus should be on enhancing the user experience through

continuous service evolution, even after mass production. I believe the true

value of SDV can be fully realized when the following three key elements are

combined.

First, the focus should be on

problem-solving rather than technology itself. The strength of SDV lies in

automakers' ability to implement the latest features faster, more

cost-effectively, and at scale across mass-produced vehicles. SDV encompasses

various technologies, such as centralized architecture and vehicle operating

systems (OS). Depending on the situation, some or all of these technologies may

be utilized. However, what matters more than the technology is the 'problem'

that the technology is designed to solve.

Second, decoupling is necessary between

automakers and controller developers, or between automakers and third parties.

Decoupling is about minimizing the impact when certain system components are

modified by reducing interdependence. By increasing the independence of system

components, software flexibility and scalability can be enhanced.

Lastly, the true value of software must be

fully recognized. It should be seen as more than just a one-time development

service but rather as a valuable product in its own right. The real competitiveness

of future mobility software lies in continuous 'maintenance,' not just in the

initial development phase. Therefore, a more effective strategy is to focus on

improving quality through ongoing development and maintenance after release,

rather than heavily investing in development costs before release.

Source=AEM

What is the core of competition in the

mobility era?

The core of competition is to continuously maximize the 'value that consumers

recognize and are willing to pay for.' In the future, 'software,' which holds

the key to this value, will determine the fundamental competitiveness of

vehicles. To achieve true service innovation, product development methods must

also shift to a software-centered approach.

FESCARO has defined this software-centric

operational management solution as 'SDO (Software-Defined Operation).' Its key

feature is the ability to centralize and manage complex, interwoven tasks

across the vehicle life cycle and the entire automotive industry value chain in

a single platform. This allows for easy and efficient tracking and analysis of

the organic impacts caused by software changes through a computerized system.

With SDO solution, automakers can streamline existing complex processes and

focus more on enhancing vehicle quality.

Please give us a real-world example of

how SDO improved productivity.

I would like to introduce a case involving an automaker and an electric vehicle

charger manufacturer.

To sell vehicles in Europe, compliance with

automotive cybersecurity (UN R155) and software update (UN R156) regulations is

mandatory. In practice, many automakers face reduced work efficiency as they

handle regulatory compliance work separately from vehicle development work. To

address this, FESCARO has developed an integrated operational management system

that minimizes work duplication, and it has already been implemented by a

global automaker.

The core function of the system is

real-time monitoring of the vehicle's cybersecurity status. When a software

defect or security event occurs during the vehicle's operation, it can be

quickly identified and addressed. Furthermore, the system allows for re-entering

the vehicle development stage to update the software, enabling the reproduction

of the vehicle with enhanced performance.

In addition, by systematically managing

information on the vehicle's software versions and history, the system allows

for proactive identification and response to potential impacts on

interconnected systems during software updates. This enables efficient

management of complex derivative and follow-up projects, optimizing operational

resources while continuously enhancing cybersecurity.

FESCARO has also applied the SDO concept to

electric vehicle chargers, where rapid identification and response to

abnormalities are critical. Issues like overheating or battery malfunctions can

lead to fires, making prompt action essential for safety.

In addition, we have developed an

integrated operational management system for Software-Defined Charger (SDC)

that enables remote management of multiple chargers distributed over long

distances. This solution, already adopted by global charger manufacturers,

allows for proactive issue resolution and damage minimization by monitoring the

real-time status of charger models and components. Furthermore, it ensures

keeping service quality at its best through OTA (Over-the-Air) updates,

enabling effective response to maintenance issues on electric vehicle chargers.

SDO shows its true value when applied to complex, interconnected tasks such as cybersecurity and software updates. By creating a system optimized to the specific environment and needs of the customer, SDO can improve work efficiency, streamline management, increase convenience, reduce costs, and shorten development cycles. Moreover, it provides a strong foundation for SDV competitiveness and serves as a proven strategy for enhancing quality post-mass production.

<Source: etnews(Ensuring the Competitiveness of Future Mobility Through Continuous Software-Based Services)>