[Series] FESCARO's Automotive Cybersecurity FAQs

FESCARO has been operating the ‘FAQs Series’ to address cybersecurity issues for stakeholders in the automotive industry. We have conducted live webinars on four key topics, and the expert panel from FESCARO provided answers to the most commonly asked questions from industry professionals. If you missed a webinar on a topic that interests you, you can access both the recorded video and a text summary (FAQs) at the following link.

# FAQs Series

1. Cybersecurity Strategies for Tiers (Emerging-OEMs oriented)

2. Comprehensive Guide on Cybersecurity Solutions & Engineering

3. Cybersecurity Testing method based on VTA Success Stories

4. ECU Cybersecurity guidance : From production to post-mass production

5. How Korea’s Motor Vehicle Management Act Amendment impacts OEMs and Tiers

The very first of webinar, <Cybersecurity Strategies 'TALK' (Emerging-OEMs oriented)> launched successfully on February!

The response was amazing! We had about 100 participants from approximately 30 different companies pre-register for the event. We have received questions from Tier companies in advance, and also those during pre-registration. We've covered a total of 7 most common concerns today.

FESCARO's experts with an average of 20 years or more of experience provided clear and insightful advice.

Let's dive in and discover the valuable insights from

• CEO Hong Seok-min, an expert in automotive cybersecurity,

• Director Ku Seong-seo, an automotive software development expert,

• Team leader Choi Kwang-mook, cybersecurity consulting leader specializing in automotive

security certification.

■ QUESTIONS LIST

![]()

■ Video Ver.

■ Text Ver.

1. What cybersecurity do OEMs require from tiers?

The cybersecurity-related requests that both domestic and global

OEMs ask to Tier companies include the following items. (Some items might vary

based on each specific OEM's requirements)

· Item (ECU) level TARA

· Cybersecurity engineering (applied with security solutions,

verified by security testing)

· Organizations and processes related to cybersecurity

· CIA (Cybersecurity Interface Agreement)

In most cases, OEMs carry out

TARA (Threat Analysis and Risk Assessment) at the actual vehicle level and determine cybersecurity goals and requirements for individual items

beforehand. For OEMs that place a strong emphasis on

cybersecurity, there are instances where they ask tiers to conduct TARA at the ECU

level. To meet security requirements,

Tiers need to create various security

applications like Secure Boot and Secure Flash for the ECU.

Additionally, security testing is crucial to ensure that the

OEM's security requirements are effectively met through these applications.

For successful engineering

activities such as cybersecurity development, verification, and operation, Tiers

must establish internal cybersecurity-related teams

and processes that align with business objectives. The prerequisite for this is to engage in R&R discussions

and finalize contracts for cybersecurity tasks between OEM and Tier, known as

the Cybersecurity Interface Agreement (CIA).

However, sometimes OEM requirements can be hard to understand or

vague. In such situations, it's best to interpret them in a way that benefits

the Tier the most while still meeting the basic criteria for OEMs to achieve

UN R155 certification. Therefore, initiating discussions with OEMs about cybersecurity tasks

right at the project's start is crucial. The cybersecurity

manager, often responsible for this, should negotiate

to benefit the Tier while meeting the minimum requirements for OEM

certification. This involves negotiating properly with the

OEM's representative to optimize the reuse of existing materials.

To do a good job as a cybersecurity manager, complete understanding about

the process of acquiring the UN R155 certification for OEM is required. To

summarize, both OEMs and tiers need to establish cybersecurity-related teams

and processes. Moreover, they determine cybersecurity goals and requirements through TARA activities conducted on the vehicle level, system level, and the

ECU level for the specific vehicle type undergoing certification.

To ensure compliance with cybersecurity requirements, OEMs create

and share precise design and validation specifications related to cybersecurity

engineering with Tiers. Since these

specifications are general and intended for multiple OEMs, it's often

challenging to address all the unique aspects of ECUs,

the specific features of new cars, and the individual characteristics of

different tiers. To bridge this gap, OEMs engage in coordination and discussions

with each tier. Using the outcomes of these discussions, they then move forward

with the cybersecurity engineering process, ultimately leading to the Start of

Production (SOP) phase.

Following the SOP, the process undergoes operational stages, including cybersecurity threat monitoring and incident response, until its scrapping(end of support). In terms of the aspects discussed earlier, the CIA plays a crucial role in defining R&R and completing the contract between the OEM and tier. To put it simply, the main approach of CIA is to maximize the reuse of existing components while ensuring the core requirements needed for the OEM's certification.

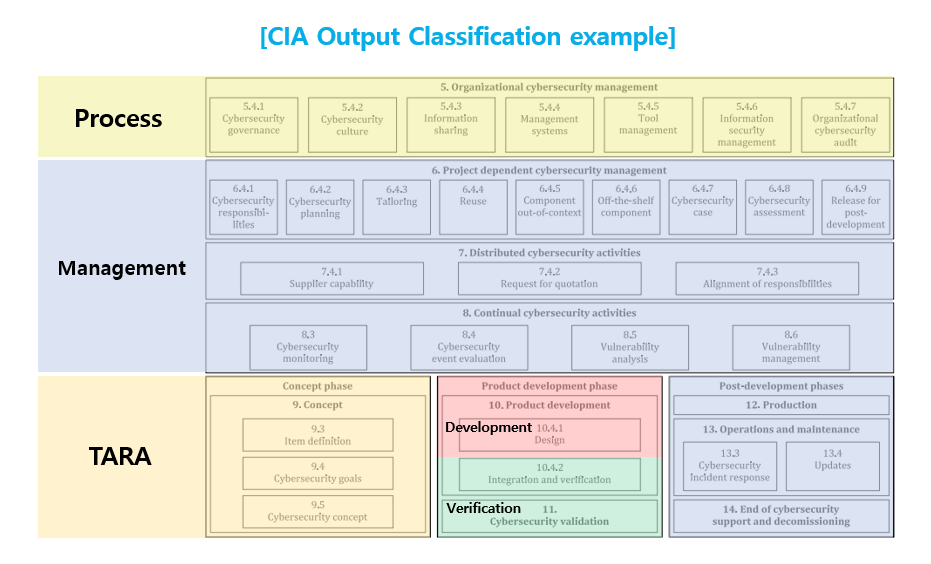

2. Do OEMs not perform TARA?

Tiers

also require TARA performance. Many people might think that TARA is done only once during the

concept phase. However, TARA is utilized not

only during the conceptual stage but also throughout the development and

post-development phases. This is due to the fact that cybersecurity risks can emerge at

any point during a vehicle's lifecycle.

![]()

When facing a cybersecurity incident, it's crucial to thoroughly

analyze the cybersecurity threat and evaluate the associated risk. TARA

represents a cybersecurity risk management approach. It classifies whether an

immediate response is necessary, whether the task should be addressed promptly,

whether collaboration with others is needed for a delayed response, and the

appropriate level of security measures required. As previously stated, TARA is a continuous

process that must be carried out across the entirety of the

project's life cycle, extending beyond the initial

conceptual stage. Hence, it becomes an essential

aspect that should be ingrained within the

tier's internal operations.

3. Where should I begin with CSMS?

From the tier's point of view, there are two ways to approach CSMS

response. The first involves setting up a cybersecurity management system in

accordance with the ISO/SAE 21434 standard. The second pertains to establishing

a dedicated system for effectively addressing the Cybersecurity Interface

Agreement (CIA) between the OEM and Tier.

The fulfillment of both aspects

can be achieved through the

establishment of a cybersecurity management system that aligns with the ISO/SAE

21434 standard. Setting up an appropriate cybersecurity

management system encompasses the following measures:

· Drafting guidelines for handling the CIA signing process between

OEM and Tier, which encompasses the cybersecurity interface agreement process.

· Establishing a comprehensive cybersecurity management system along

with corresponding rules, including the cybersecurity organization.

· Developing guidelines for conducting cybersecurity Threat Analysis

and Risk Assessment (TARA) activities.

· Defining procedures for integrating and verifying OEM’s

cybersecurity requirements.

· Creating guidelines for the application of cybersecurity

principles within production processes.

· Creating a system that actively monitors cybersecurity-related

information and events, while also conducting analysis and management of

identified vulnerabilities.

· Formulating guidelines for the appropriate response in the event

of a cybersecurity incident.

By implementing this

cybersecurity management system, you will be well-equipped to address a multitude of requirements coming from OEMs in the field

of cybersecurity. Building a cybersecurity management system in accordance with

ISO/SAE 21434 can be challenging, as knowing where to begin and how to proceed

might not be straightforward. In practice, achieving this without expert

guidance, such as professional consulting, can be daunting. Therefore, both

OEMs and many tiers often seek assistance from specialized companies like us to

navigate this complex process effectively. Ultimately, however, it is necessary

to internalize this cybersecurity

management system.

![]()

From a professional consulting perspective, the process of

establishing a cybersecurity management system can be categorized into three

distinct stages. First, the consulting service conducts

a gap analysis aimed at designing and constructing a

cybersecurity management system tailored to the organization's

existing circumstances.

Second, a cybersecurity

internalization project is chosen, and the consulting service guides the

organization through the process of project

implementation in accordance with the established procedures. We assist in planning and setting

up teams for projects related to cybersecurity response, help with the CIA

contract signing process, and provide support for the TARA process. TARA

experts are dispatched when necessary. We also support designing, applying, and

validating security solutions during product development. The red team will be

put in if necessary. Also, we provide help for ensuring security during

production, and assist in monitoring events, and managing vulnerabilities

throughout the entire life cycle of the vehicle.

Thirdly, ISO/SAE 21434 mandates

cybersecurity audits and project assessments,

and we back up this process. Addressing process audits for each project places

a significant burden on development and quality teams. To counter this

challenge, obtaining a dependable CSMS

certification can enhance productivity significantly.

4. I want to reuse the results of previous projects in new projects.

The extent of work for

cybersecurity deliverables is established via the Cybersecurity Interface

Agreement (CIA) established between the OEM and Tier. Every output mentioned in the CIA can be

categorized into either reusing an existing

output or generating a new one.

The decision to reuse these

artifacts should be made after thoroughly examining the

item definition and cybersecurity specifications. When conducting an item definition review, it's important to

pinpoint any alterations in item functionality, security assets, or

modifications to the operating environment. Similarly, during a cybersecurity

specification review, the focus should be on recognizing any shifts in security

requirements or security controls.

To facilitate the process of output reuse, CIA outputs can be

conveniently organized and categorized as follows. The majority of cybersecurity "process" outputs are

mostly suitable for reuse, whereas "management" outputs demand guided adjustments. "TARA and Verification" outputs can be reused, but it's important to factor in any modifications in

cybersecurity specifications, the operating environment, and related threat

scenarios or vulnerabilities. "Cybersecurity development" outputs are generally reusable, although changes to the cybersecurity specifications

need consideration. In essence, with the exception of chapters

9, 10, and 11, a substantial portion of the outputs can be readily reused.

It's essential to conduct a reuse analysis specifically for the deliverables of

chapters 9, 10, and 11. For example, if it’s decided to add new cybersecurity features,

that means changes to the security functions in the product is necessary. And

not only that, verification testcase also needs to be modified. Here's another

example, even if the product specifications

do not change, if the environment it's used in changes, additional TARA process

is needed. Also, when we bring in an external connection, we have to include

more security measures. And if the vehicle protection model changes, it affects

how we assess security risks. In simple terms, based on the reuse analysis

results, we can decide whether to change specifications or design.

5.

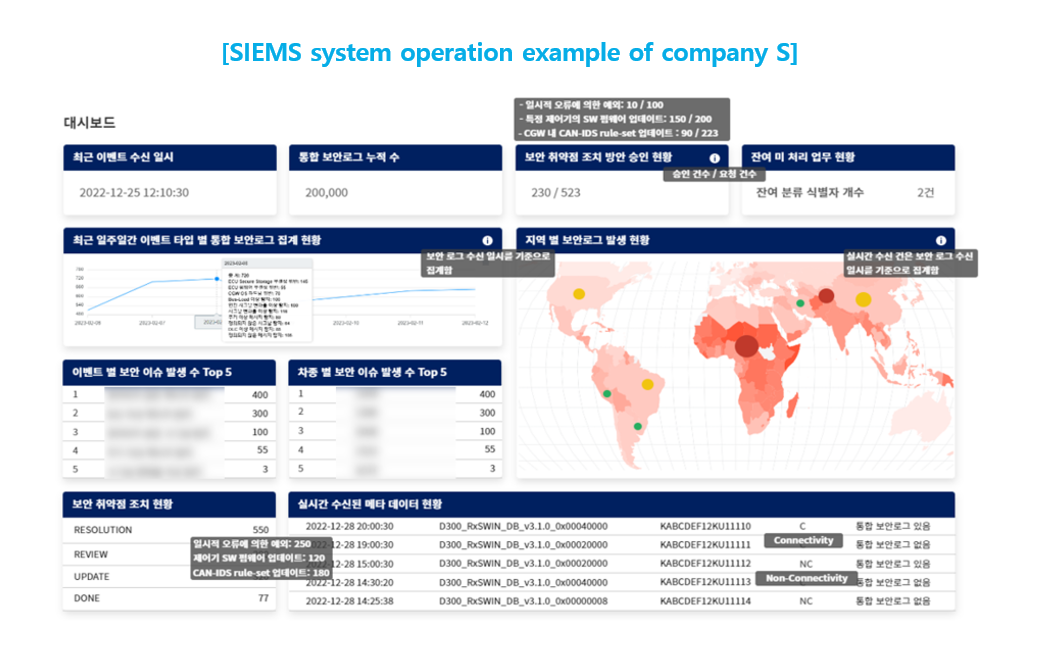

When it comes to cybersecurity vulnerability management, there are two important aspects to consider. First, it's important to handle security vulnerabilities from the development phase to SOP, and throughout the entire life cycle after SOP. Second, we need to take care of vulnerabilities found in different sources.

When it comes to cybersecurity, it's crucial to know that security

breaches can happen even after the SOP (Start Of Production), when the product

development is completed. This is because the development of hacking technology

from hackers are faster than the development of security solutions.

So, whenever there's a security breach or a cybersecurity incident, we have to develop, verify and distribute the security measures, and this has to be repeated throughout the whole life cycle of the vehicle. Normally, when SOP duration is 5 years and the warranty covers 10 years, it will be a total of around 15 years, and in reality, it might even be closer to 20 years. But the current security technology cannot withstand throughout the whole period. That is why it's important to conduct ISO/SAE 21434 Chapter 8 ‘Ongoing cybersecurity activities. Let's see with specific examples.

![]()

This screen is an example of a vulnerability management ledger.

The sources where vulnerabilities emerge are varied as in the picture.

There can be vulnerabilities from

cybersecurity information and event monitoring, risk list from TARA,

vulnerabilities emerged from project development/verification, security

breaches from the field after SOP. Just like in this example, it's important to

keep a record of vulnerabilities for each project. This is because as mentioned

earlier, the vulnerabilities have to be handled according to the specific

project's traits. And the cybersecurity tasks need to follow the rules in

Chapter 8 of ISO/SAE 21434, which is the 'Guidelines for Ongoing Cybersecurity Activities’.

[ ISO/SAE 21434 Chapter 8 'Guidelines for Ongoing Cybersecurity Activities' ]

· Implement/record of cybersecurity information and event monitoring

· Evaluate whether an identified event is a security weakness

· Check through TARA if the weakness could be a vulnerability in the

project

· Vulnerability management throughout the product life cycle

To internalize the management of cybersecurity vulnerabilities, it is a best practice to build and operate SIEMS (Security Information and Event Management System) system. With this system, it is possible to manage the entire cybersecurity issues and the current situation comprehensively.

6. Every meeting with OEMs leads to more follow-up work due to a lack of cybersecurity knowledge.

We often come across this question when

we communicate with ECU manufacturers, and it's a

challenge we've faced a lot. We've covered a similar kind of

response strategy earlier, and to handle the different requests from OEMs

effectively, it's crucial to have standardized and strategic

response processes.

· Tailoring security requirements

according to product characteristics

· Minimizing modifications due to

changes in OEM's needs by creating outputs following international standards

In general, OEMs have

certain standard requirements for cybersecurity features. However, these

requirements are usually a superset. Since the features of

each ECUs are different, it is hard to apply in entirely. It's

important to really understand what OEMs are requesting and identify what is capable of what is not. If there are things not possible to do, showing different options or explaining why it's not possible is required. And if it's needed,

suggesting plans for what to do next is necessary.

OEMs will take the information provided by these ECU manufacturers to get the type certification. When we look at it from the perspective of the CIA (Cybersecurity Interface Agreement), it's tough for the ECU manufacturers to respond since each OEM's product requirements are different. To work around these challenges, It must be written based on the ISO/SAE 21434 standard and sufficiently explained that it satisfies the international standards to minimize repetition or modification of work.

But the real challenge is that a lot of ECU manufacturers don't

have a dedicated cybersecurity team, which makes it tough to handle the tasks.

The more you discuss with OEMs, the more confusion tends to arise,

making the workload even heavier. To tackle these issues, having experts with

specialized security skills would be a great help. Companies like FESCARO could be

an alternative.

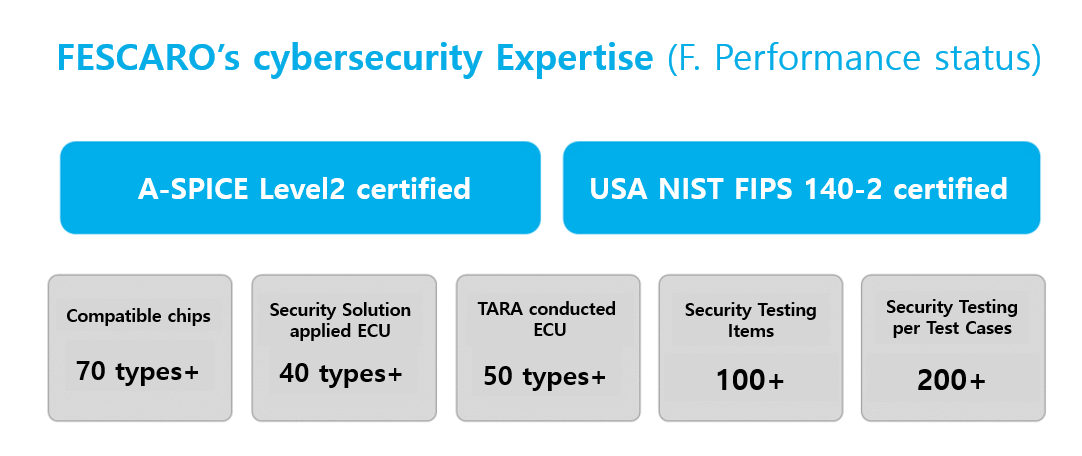

FESCARO currently offers CSMS consulting,

security solutions, and security testing services for local OEMs. We are well-versed in what ECU manufacturers have to

do in order for OEMs to achieve the UN R155 certification, and have a track record

of assisting multiple ECU manufacturers with CSMS consulting, cybersecurity

manager responses, security solutions, and engineering services. We

are here

to provide a clear guide for you to navigate these tasks effectively.

7. Are cybersecurity certifications required for tiers?

In simple terms, no. To clarify, the certification is only required for car manufacturers. UN R155 states that CSMS certification must be obtained by car manufacturers. However in CSMS, it is required to manage the cybersecurity activities of the ECU manufacturers as well.

The detailed process for this is

explained in Chapter 7, 'Distributed Cybersecurity Activities,' of ISO/SAE

21434. The OEM verifies if the ECU manufacturer has established CSMS by using the CIA (Cybersecurity

Interface Agreement). Even though the ECU manufacturers don't directly

have to get

certified, it's required to create

CSMS as per the OEM's requirements. Certain ECU manufacturers might even

earn CSMS certification through a certification body like TS (Technical Service) and get the ISO/SAE 21434

certification.

This certification offers the

reassurance that the company is well-prepared for cybersecurity, giving you an advantage when pursuing

different projects or new projects with OEMs. Certification

bodies currently lack formal certification qualifications or auditor

qualifications. Because of this, organizations like TS are taking on the role

of UN R155 certifications and carrying out ISO/SAE 21434 certifications for tiers.

FESCARO is working in collaboration

with several TS companies, and there have been instances where ECU manufacturers that we have consulted achieved ISO/SAE

21434 certification. Drawing from this collaborative partnership and the

experience gained,

FESCARO is dedicated to providing comprehensive support to ECU manufacturers, ensuring

them to successfully

attain certification.

FESCARO has secured CSMS certification from OEMs and ISO/SAE 21434

certification from Tiers.

Our expertise encompasses cybersecurity consulting and engineering

services for a wide range of ECU used in both internal combustion engine vehicles and electric vehicles.

-

PREV No previous post.

-

NEXT [FAQs] Comprehensive Guide on Cybersecurity Solutions & Engineering